Description

Sealed Chain 420RO – O-Ring motorcycle chain for 100cc Applications

In small-displacement motorcycles, drivetrain reliability plays a critical role in overall vehicle performance and service life. For OEM manufacturers, distributors, and aftermarket suppliers, selecting a Sealed Chain that delivers stable performance while controlling long-term maintenance costs is essential.The 420RO O-Ring Sealed Chain is engineered specifically for motorcycles up to 100cc. It combines proven sealing technology, standardized dimensions, and consistent manufacturing quality, making it a practical choice for high-volume B2B supply programs.

Why Choose a Sealed Chain for Small-Displacement Motorcycles?

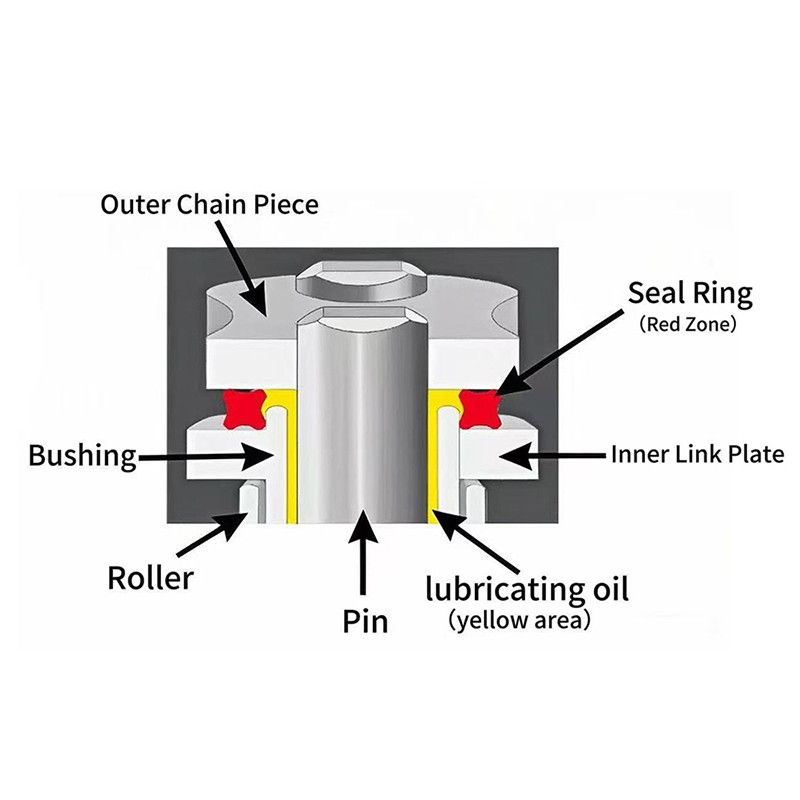

Conventional non-sealed chains often suffer from rapid lubricant loss, accelerated pin and bushing wear, and frequent elongation caused by dust, water, and daily stop-and-go riding conditions. These issues increase maintenance frequency and shorten replacement cycles.A Sealed Chain solves these problems by retaining factory-applied lubrication inside the chain joints while preventing external contaminants from entering critical wear areas. This results in smoother power transmission, reduced friction, and significantly longer service intervals.

420RO as an O-Ring Sealed Chain Solution

The 420RO belongs to the O-Ring Sealed Chain category, the most widely used sealing structure for small and mid-displacement motorcycles. Elastic O-rings are installed between the inner and outer plates, creating an effective seal around each pin and bushing.Key benefits of the O-Ring design include:

- Long-term lubrication retention

- Reduced internal wear and chain stretch

- Stable performance under daily commuting conditions

- Balanced cost compared with more complex sealing systems

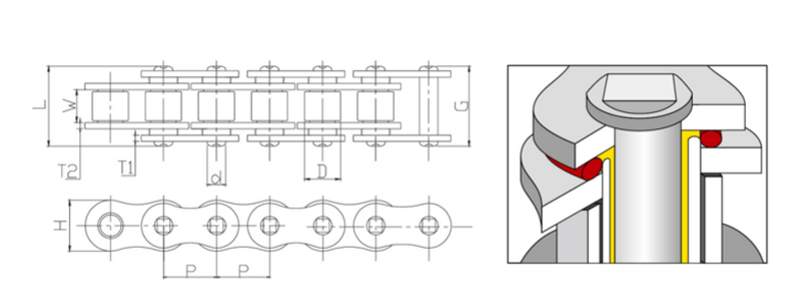

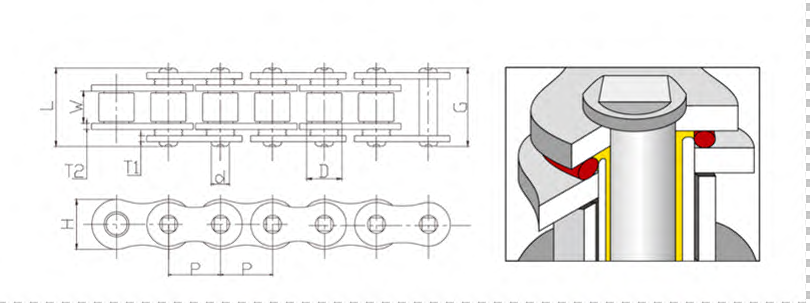

Technical Specifications (420RO Standard)

| Model | Pitch P(mm) | Inner Link Min Width W(mm) | Roller Max OD D(mm) | Outer Plate Thickness T1(mm) | Inner Plate Head Thickness T2(mm) | Inner Plate Head Width H(mm) | Pin Diameter d(mm) | Pin Length L(mm) | Boss Length G(mm) | Min Tensile Strength(Kgf) | Avg Tensile Strength(Kgf) | Max Displacement(cc) |

| 420RO | 12.7 | 6.25 | 7.77 | 1.5 | 1.5 | 11.8 | 3.95 | 17 | 18.6 | 1640 | 1850 | 90 |

Engineered for Durability and Consistent Performance

The 420RO Sealed Chain features a dual-bridge plate structure that improves load distribution and reduces shifting impact. The chain surface undergoes professional anti-corrosion treatment, combined with Ti-CN (Titanium Carbon Nitride) coating technology, enhancing surface hardness and wear resistance.Under normal lubrication conditions, the chain can achieve 20,000 km or more of stable service life, helping distributors and OEMs reduce warranty claims and after-sales costs.

Installation-Friendly Design for Workshop Efficiency

To simplify installation and maintenance, the 420RO is designed with:- A figure-8 clip-type connecting link

- Non-directional chamfered edges

- Compatibility with standard chain tools

Applications and Compatibility

This O-Ring Sealed Chain is widely used in:- ≤100cc commuter motorcycles

- Mini bikes and monkey bikes

- Light-duty off-road and ATV applications

-

Value for B2B Buyers

Choosing the 420RO Sealed Chain means:- Lower total cost of ownership

- Stable quality across bulk orders

- Reduced maintenance and replacement frequency

- Reliable long-term supply for aftermarket and OEM channels

Maintenance Recommendations

For optimal performance:- Lubricate the chain regularly

- Re-oil after riding in rain or washing the motorcycle

- Use sealed-chain-specific lubricants in dusty environments

Product Positioning Summary

The 420RO O-Ring Sealed Chain is not over-engineered—it is engineered for reliability, consistency, and value.For B2B customers supplying small-displacement motorcycles, it delivers dependable performance without unnecessary cost, making it a smart Sealed Chain choice for long-term business growth.