Description

#25 Standard Roller Chain

Reliable ANSI B29.1 Chain for Light-Duty Power TransmissionIn light-duty power transmission systems, consistency matters more than extremes. The #25 standard roller chain is widely used in compact machinery, automation modules, and precision-driven equipment where smooth operation, dimensional accuracy, and long service life are critical.

Wonkechain’s #25 roller chain is manufactured in full compliance with ANSI B29.1 standards, ensuring reliable interchangeability with sprockets and drive components used across North American and European industrial systems.

Why #25 Roller Chain Is Widely Used in Industrial Applications

For system integrators, equipment manufacturers, and maintenance teams, #25 roller chains are often selected to solve three practical challenges:1. Stable Power Transmission in Compact Systems

#25 chains are designed for low to moderate loads, making them ideal for compact drives where space is limited but timing accuracy is essential. Uniform pitch and controlled tolerances help reduce vibration and speed fluctuation.2. Reduced Wear and Maintenance Frequency

In small machinery, chain elongation directly affects positioning accuracy. Our #25 roller chains use high-quality carbon steel and controlled heat treatment to maintain pin and bushing integrity, helping slow down wear during continuous operation.3. Easy Replacement and Global Compatibility

Because the chain strictly follows ANSI B29.1 dimensions, it can be easily replaced without redesigning sprockets or shafts—an important cost-saving factor during maintenance or system upgrades.Typical Applications of #25 Standard Roller Chain

The #25 roller chain is commonly used in:- Small automation and conveyor modules

- Packaging and labeling equipment

- Light-duty power transmission systems

- Laboratory instruments and testing rigs

- Educational and training machinery

Engineering & Manufacturing Focus

Instead of emphasizing appearance or short-term performance, Wonkechain focuses on long-term operational stability:- Precisely machined pins and bushings to ensure smooth articulation

- Controlled heat treatment for balanced hardness and toughness

- Consistent material sourcing to minimize batch-to-batch variation

- Quality inspections aligned with ANSI dimensional requirements

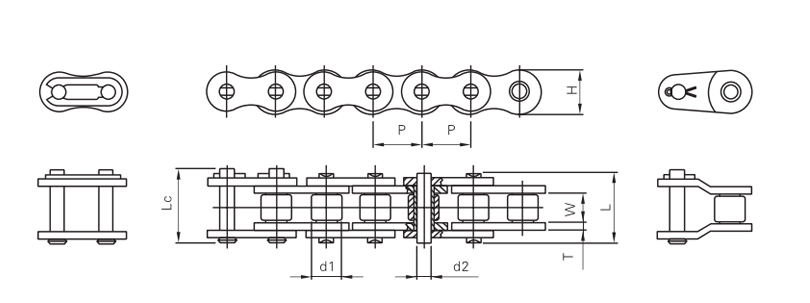

#25 Standard Roller Chain – Specifications

| ANSI Chain No. | Pitch | Inner Width | Roller Diameter | Pin Diameter | Pin Length | Pin Length | Plate Width | Plate Thickness | Minimum Tensile Load | Average Tensile Load | Working Load |

| (P) | W( min) | (d₁ max) | (d₂ max) | (L max) | (Lc max) | (H max) | (T) | (min) | (max) | ||

| (millimeter) | (millimeter) | (millimeter) | (millimeter) | (millimeter) | (millimeter) | (millimeter) | (millimeter) | (kilogram-force) | (kilogram-force) | (kilogram-force) | |

| 25 | 6.35 | 3.1 | 3.3 | 2.31 | 8 | 8.8 | 6.02 | 0.75 | 360 | 400 | 65 |

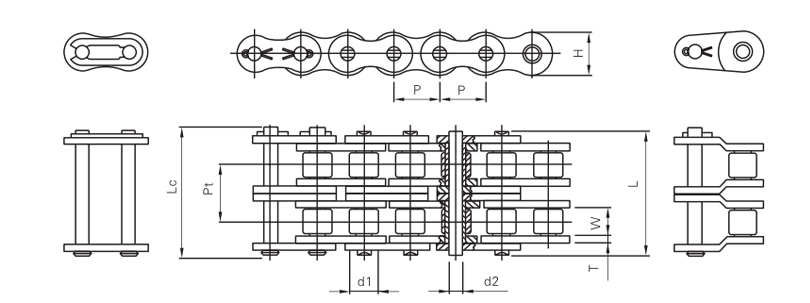

| ANSI Chain No. | Pitch (mm) | Inner Link Width | Roller Outside Diameter | Pin Outside Diameter | Pin Length | Pin Length | Plate Width | Plate Thickness | Minimum Tensile Load | Average Tensile Load | Working Load | Pitch |

| P | W min | d₁ max | d₂ max | L max | Lc max | H max | T | min | max | Pt | ||

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kgf) | (kgf) | (kgf) | (mm) | |

| 25-2 | 6.35 | 3.1 | 3.3 | 2.31 | 14.5 | 15.2 | 6.02 | 0.75 | 720 | 860 | 110 | 6.4 |

How to Select the Right #25 Roller Chain for Your System

Before choosing a #25 chain, engineers typically evaluate:Required working load vs. safety factor

Operating speed and duty cycle

Environmental conditions (dust, moisture, temperature)

Compatibility with existing sprockets

If you’re unsure, selecting a chain that meets ANSI standards with proven dimensional stability is usually the safest starting point.

Conclusion

The #25 standard roller chain remains a practical and cost-effective solution for light-duty industrial power transmission. By focusing on dimensional accuracy, material consistency, and ANSI compliance, Wonkechain delivers chains that integrate smoothly into real-world machinery—not just on paper specifications.If you need technical support or help selecting the right configuration, our team is ready to assist.