Description

Optimize Your Bottle Washing Line with Our Conveyor Chains

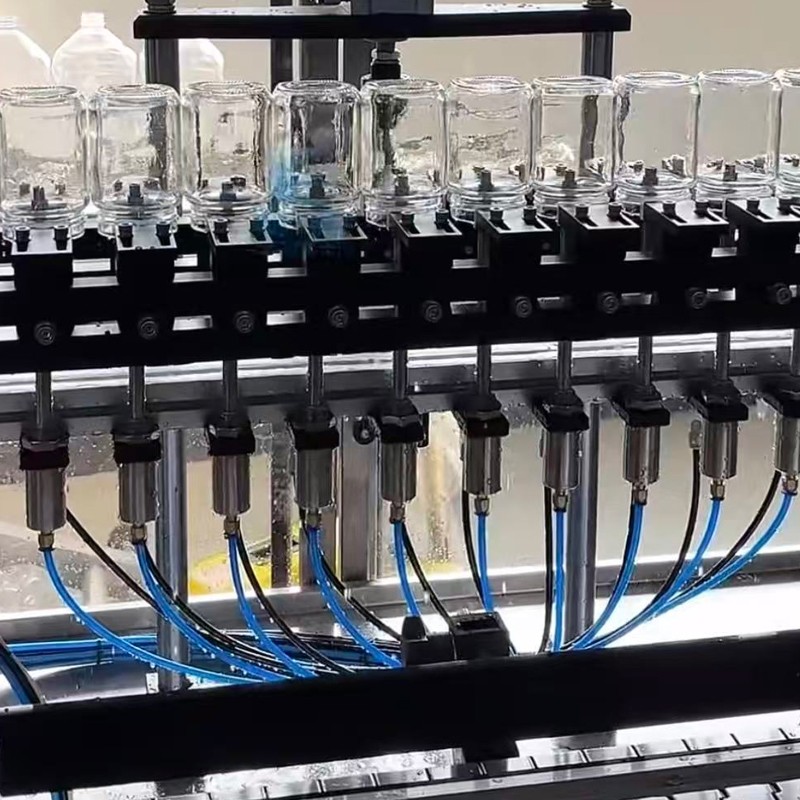

Our Bottle Washer Conveyor Chains are specifically designed for glass bottle and can cleaning lines in the beverage and pharmaceutical industries. Built to withstand harsh detergent baths and abrasive residues from recycled bottles, these chains ensure balanced operation, smooth power transmission, and maximum durability—keeping your production line efficient and reliable.

Key Features and Advantages

Designed for Harsh Environments

Operates fully immersed in cleaning baths with detergents, resistant to oxidation and corrosion.Handles abrasive residues from dirt, label decomposition, and recycled bottles without lubrication.

Engineered for smooth, balanced operation even under demanding conditions.

Specialized Attachments

Two typical chain types: welded attachments for heavy loads and bent attachments for flexible applications.Attachments use screws to secure crossbars that transport bottles loaded into special cells, ensuring stable and safe handling.

Customizable to fit your production line requirements.

Optimized Materials & Heat Treatment

Carefully selected materials and precise heat treatment extend chain life.High wear resistance and corrosion protection minimize downtime and maintenance costs.

Designed to deliver maximum value over the chain’s lifetime.

Applications in Beverage and Pharmaceutical Industries

Beverage Industry: Glass bottles, soft drinks, beer, and other beverage containers. Handles recycled bottles efficiently.Pharmaceutical Industry: Glass vials, medicine bottles, and cans, compatible with sanitary cleaning processes.

Reduces production interruptions and ensures smooth operation even at high speed.

Benefits for B2B Buyers

Reduce Downtime: Balanced operation prevents jams caused by dirty or recycled bottles.Lower Maintenance Costs: Durable materials and optimized design extend service life.

Increase Efficiency: Smooth and reliable movement ensures fast and safe bottle transport.

Adaptable Design: Welded and bent attachments provide flexibility for various line configurations.

Factory-Direct Supply: Quality-controlled chains shipped directly from our China factory.

Technical Specifications

|

Feature |

Details |

|---|---|

| Chain Types | Welded Attachment, Bent Attachment |

| Applications | Beverage & Pharmaceutical Bottle Washing Lines |

| Materials | Heat-treated steel, corrosion-resistant coating |

| Sizes | Customizable to line requirements |

| Environment | Fully immersed in detergent baths, non-lubricated |

FAQ

Q1: Can these chains handle recycled bottles with dirt and labels?

A1: Yes, our chains are engineered for abrasive residues and operate reliably in detergent baths without lubrication.

Q2: What attachments are available for these conveyor chains?

A2: We provide welded and bent attachments. Screws on attachments secure crossbars to transport bottles efficiently.

Q3: Are these chains suitable for pharmaceutical bottle washing lines?

A3: Absolutely. Chains are designed for glass vials, medicine bottles, and cans, supporting sanitary cleaning processes.

Q4: How long do these chains last?

A4: With optimized materials, heat treatment, and corrosion resistance, our chains offer long service life and reduced maintenance requirements.

Q5: Can I order customized chain sizes?

A5: Yes, chains can be customized to match your specific production line requirements.

Why Choose Our Bottle Washer Conveyor Chains?

Our chains are not just components—they are solutions for your production line challenges. Designed for B2B buyers who need reliability, durability, and efficiency, our chains ensure:- Reduced downtime and maintenance costs

- Smooth, safe bottle transport

- Long-lasting performance in harsh detergent environments

- Flexibility for different conveyor configurations

- Factory-direct quality with strict quality control

Upgrade your bottle washing line today with Bottle Washer Conveyor Chains engineered for maximum efficiency and reliability.