Description

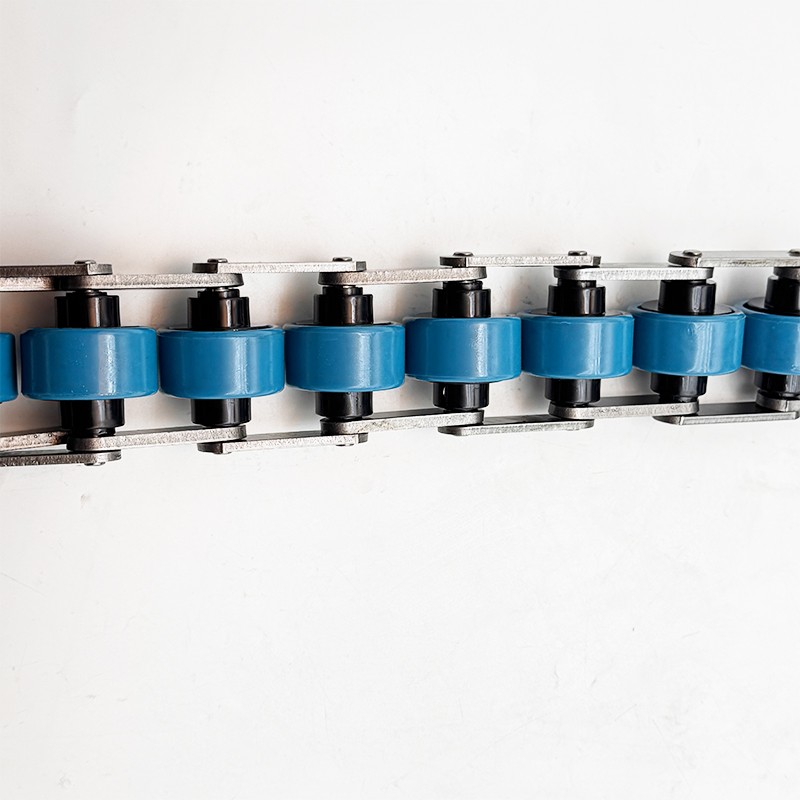

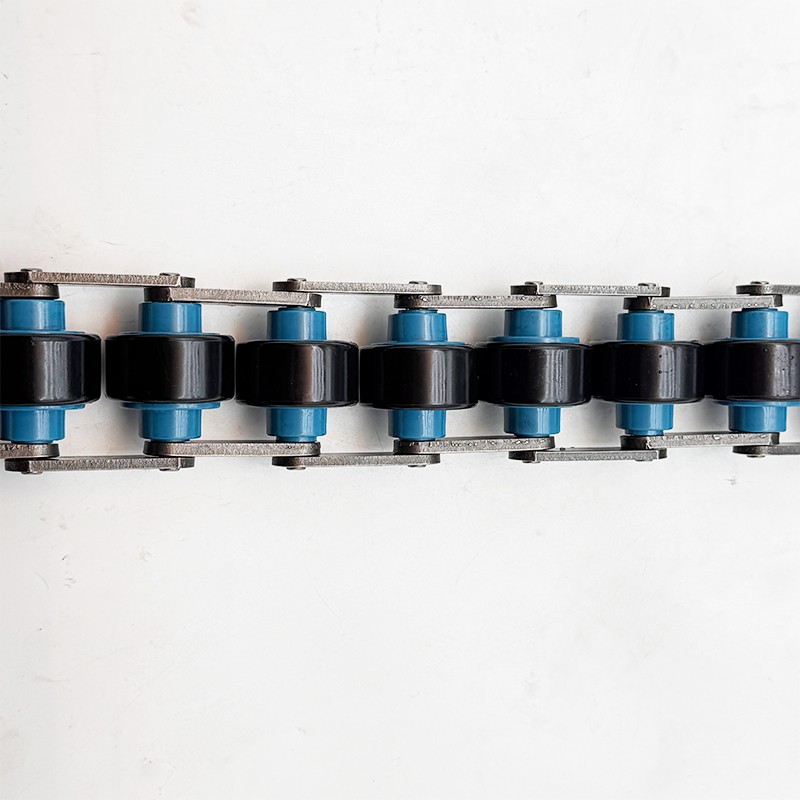

Accumulation Chain (Double Plus Chain)

High-Speed Accumulating Conveyor Chain for Automated Assembly LinesThe accumulation chain, also known as a double plus chain, is a core conveying component in modern automated assembly lines. It is specifically designed to achieve free-cycle operation, precise positioning, and accumulation conveying, allowing production systems to run more efficiently and flexibly.

By separating fixture movement from chain movement, accumulation chains enable higher throughput without increasing conveyor length, making them ideal for electronics, home appliance, automotive, machinery, and logistics applications.

Core Working Principle

The accumulation chain is based on a coaxial double-diameter roller design. Each chain link is equipped with both a small roller (d) and a large roller (D). While the chain moves at a constant speed v₀, the fixture plate travels on the large rollers at a higher speed:Fixture speed v ≈ (D / d) × v₀

Common speed ratios include single speed, 2.5× speed, and 3× speed, with 2.5× and 3× being the most widely used in automated production lines.

Free-Cycle Accumulation Operation

During operation, the chain runs continuously along the guide rails, while fixture plates roll freely on the large rollers. At each workstation, a stopper precisely halts the fixture plate for assembly or inspection. Once released, the fixture immediately resumes high-speed movement.This mechanism allows:

- Independent station cycle times

- Accumulation and buffering

- Reduced start-stop stress on the chain

- Stable, continuous line operation

Structure and Materials

Chain Structure

- Inner and outer chain plates

- Pins and bushings

- Large and small rollers

- Retaining rings

Supporting System

- Drive unit (motor + reducer)

- Tensioning system

- Aluminum alloy guide rails

- Fixture plates and stoppers

- Lifting, transfer, and return modules

Material Options

Rollers: Engineering plastic (low noise, light load) or steel (heavy load, high wear resistance)Chain plates: Carbon steel or stainless steel for different environments

Key Advantages

- High Efficiency – Fixture plates move up to 3 times faster than the chain, significantly reducing cycle time.

- Flexibility – Free-cycle operation supports accumulation, line switching, and multi-process integration.

- Stability – Rolling friction design ensures low noise, low wear, and long service life.

- Scalability – Modular system allows easy expansion and layout adjustment.

Typical Applications

- Electronics and electrical appliance assembly lines

- Automotive parts assembly and inspection lines

- Machinery and precision component production

- Automated logistics and warehouse conveying systems

Technical Specifications

| GB/TB Chain No. | Pitch P (mm) | Roller Size di max (mm) | Roller Size d8 max (mm) | Roller Size b1 max (mm) | Roller Size b8 max (mm) | Pin Size d2 max (mm) | Pin Size L max (mm) | Pin Size Lc max (mm) | Link Plate Size H max (mm) | Link Plate Size T max (mm) | Link Plate Size t max (mm) |

| BS25-C208A | 25.4 | 15.88 | 24.6 | 5.7 | 10.3 | 3.96 | 31 | 32.8 | 11.7 | 1.5 | 2 |

| BS25-C210A | 31.75 | 19.05 | 30.6 | 7.1 | 13 | 5.08 | 39.5 | 41.2 | 15 | 2 | 2.4 |

| BS30-C212A | 38.1 | 18 | 38 | 9.57 | 20 | 5.94 | 58.1 | 62.7 | 15 | 3.2 | 4 |

Selection and Maintenance Guide

Selection:Choose roller material based on load, select speed ratio according to cycle time, and determine stopper and positioning mechanisms based on accuracy requirements.

Maintenance:

Regularly check chain tension, keep guide rails clean, apply proper lubrication, and avoid overloading or foreign object obstruction.

Reliable Accumulation Chain Solution

As a professional manufacturer of accumulation chains and double plus chains, we provide stable quality, engineering-level support, and customized solutions for automated production lines.Contact us to improve the efficiency and flexibility of your conveying system.